Feeding employees better with the new generation of food vending machines and ordering processes: Healthy, fresh and sustainable.

Vending machines and healthy eating? A contradiction in terms for years. The snacks sold were too unhealthy, the food too unappetizingly overstocked. Digitalization is changing all that. Modern vending machines can be (pre-)ordered and paid for simply by app. In conjunction with additional frozen, microwave and return machines, small company restaurants can be established: Healthy catering for employees, 24/7. Stocking according to demand and the integration of reusable packaging systems make the concept sustainable.

Fresh goods thanks to advance ordering. Food waste can be minimized by stocking according to demand.

Pre-ordering food from vending machines opens up new scope for caterers: they know the demand in advance and can stock the machines accordingly. This minimizes the risk of food remaining in the vending machine for too long, not being collected and ultimately spoiling. Of course, there is still room to stock the vending machines with additional products for spontaneous purchases.

Types of vending machines: the right device for every requirement

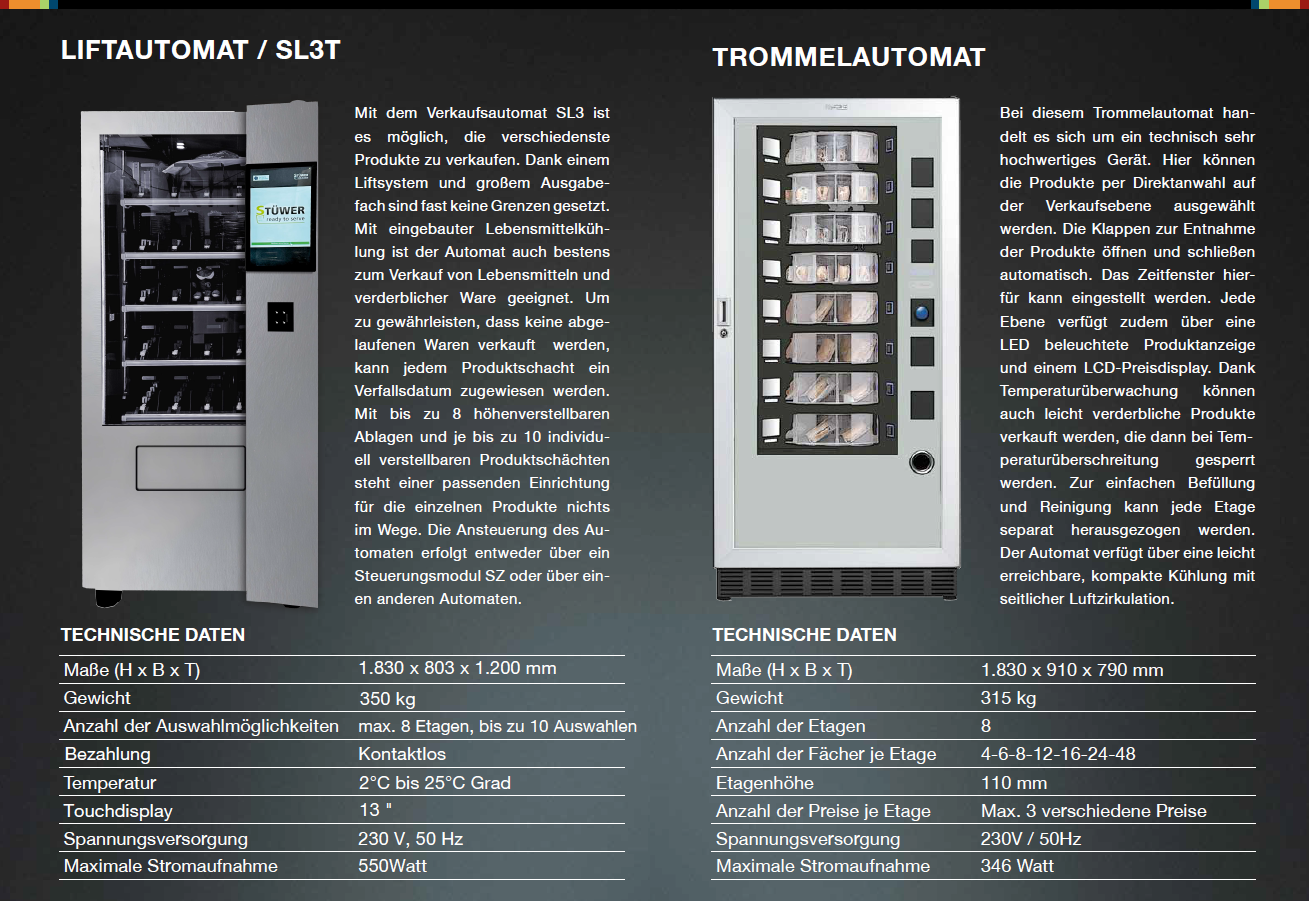

Vending machine

Drum and lift vending machines have established themselves as food vending machines. Thanks to flexibly divisible surfaces, they offer space for numerous products in different sizes. Thanks to temperature monitoring, perishable products can also be sold. This makes it possible to offer a wide and, above all, fresh range of products.

Lift machines are particularly suitable for products that need to be handled gently, such as lettuce, eggs, or products in glass packaging: the lift system ensures gentle dispensing.

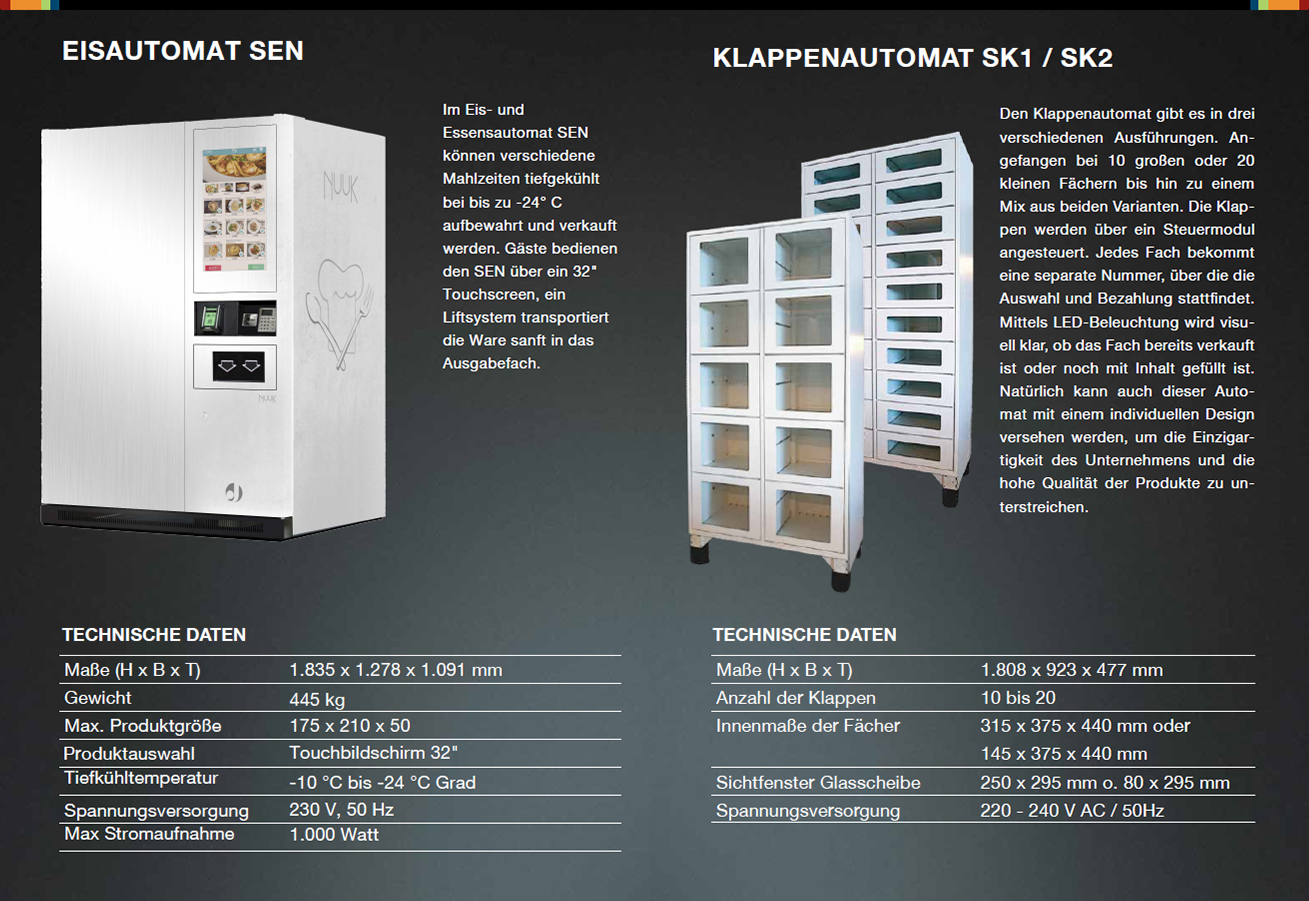

Freezer module and microwave oven:

The freezer and microwave module extend the round-the-clock catering service: Caterers can offer frozen meals as well as ice cream. On the other hand, the microwave module allows the food on offer to be heated quickly and easily. The QR code on the reusable packaging also serves as preparation instructions: the microwave vending machine can automatically heat the food ready to eat.

Return machine:

The return machine takes back reusable crockery and credits the return information directly to the customer: simply place the crockery items one after the other. The QR code releases the tilting device and the crockery items fall into the storage container. The returned plates, bowls and cups are stored properly at up to 2 degrees Celsius.

The SL3 vending machine is used to sell a wide variety of products. The lift system with large dispensing compartment sets almost no limits. With built-in food refrigeration, the vending machine is ideal for selling food and perishable goods.

To ensure that no expired goods are sold, the picker assigns an expiry date to each product slot. With up to 8 height-adjustable shelves and up to 10 individually adjustable product compartments, there is nothing to stop you from setting up the right equipment. The vending machine is controlled either via a SZ control module or via another vending machine.

This drum vending machine is a technically sophisticated appliance. Users select the products directly on the sales level. The flaps for removing the products open and close automatically. The time window for this is set. Each level has an LED-illuminated product display and an LCD price display. Thanks to temperature monitoring, perishable products can also be sold - they are blocked if the temperature is exceeded. Each shelf can be pulled out separately for easy filling and cleaning. The vending machine has an easily accessible, compact cooling system with lateral air circulation.

The ATB is an attractive alternative for offering a wide range of products: the products range from honey jars and egg boxes to baskets filled with specialties.

The ATB drum vending machine is equipped with overhead cooling and the temperature is freely adjustable. The height of the shelves is determined when the order is placed. This allows 3 to 8 shelves and 18 to 48 compartments on just under one square meter of sales area.

The flap dispenser is available in three different versions. Starting with 10 large or 20 small compartments through to a mix of both versions. The flaps are controlled via a control module. Each compartment is given a separate number, which is used for selection and payment. LED lighting makes it visually clear whether the compartment has already been sold or is still full. The vending machine can be given an individual design.

The EMW microwave module can be attached as a supplement to a lift vending machine, for example. This makes it possible to offer fresh ready meals from the vending machine and heat them up ready to eat directly via the microwave from the EMW. The EMW microwave module can heat up to 3 meals at the same time, reducing waiting times in front of the vending machine. The optimum cooking time can be stored in the microwave for all meals - scanning the QR or barcode takes care of the rest. Up to 12 microwaves can be connected to each control unit.

The return machine takes back reusable crockery and credits the return information directly back to the customer: simply place the crockery items one after the other. The QR code releases the tilting device and the crockery items fall into the storage container. The returned plates, bowls and cups are stored properly at up to 2 degrees Celsius.